A digital video interface link and protocol used for high-speed digital video display data transfers are defined by the industry standard ARINC-818 Specification.

This specification provides a common link and protocols that handle high-bandwidth data, especially for digital video applications, allowing data production units and display devices operating in aerospace applications to make use of them.

Numerous video formats are now used in aerospace applications. The frame rates, resolutions, pixel densities, and interlacing methods of different video formats vary. All of these video formats are constructed and mapped to the industry standard Fibre Channel according to the ARINC-818 Specification.

In this blog, we will delve into the ARINC 818 testing and validation, best practices, and challenges of ARINC818 testing and validation.

What is ARINC 818

The video interface and protocol standard known as ARINC 818: Avionics Digital Video Bus (ADVB) was created for high bandwidth, low latency, uncompressed digital video transmission in avionics systems.

Since its publication in January 2007, the aerospace community and ARINC have worked to develop the standard to satisfy the demanding requirements of high-performance digital video.

After revisions to the standard, ARINC 818-2 was published in December 2013 with a number of new capabilities, such as data-only links, bi-directional control, field sequential color, channel-bonding, switching, and link rates up to 32X fiber channel rates.

In 2018, ARINC 818-3 was made available. In addition to addressing several questions, this patch addressed the differences between the 8b/10b and 64b/66b encoding rates.

Despite being more straightforward, ADVB keeps several of the features of Fibre Channel that are useful for mission-critical applications: Fast, dependable, flexible, low latency, high performance, and uncompressed digital video transmission

Overview of ARINC 818 protocol

The 8b/10b-encoded (or 64B/66B for faster rates) point-to-point serial protocol known as ARINC 818 (Avionics Digital Video Bus) is used to transmit data, audio, and video.

While packetized, the protocol is video-centric and highly flexible, allowing for the multiplexing of several video streams on a single channel or the transmission of a single stream over two links, among other complicated video functionalities.

There are four distinct classes of video synchronization specified, ranging from straightforward asynchronous systems to intricate pixel-synchronous systems. Since ARINC 818 (ADVB) is unidirectional, handshaking is not necessary. The 15 defined speeds of ARINC 818 (ADVB) range from 1 Gbit/s to 28 Gbit/s.

An Interface Control Document is necessary for every ADVB project (ICD). The ICD, which is shared by every project participant, guarantees interoperability, scales back the implementation, and specifies:

- Video format(s) for the project

- Embedded data (Ancillary Data)

- Video and line timing

- Pixel format

- Synchronization class

Testing ARINC 818 Systems

A system’s functionality, dependability, and conformance to industry standards must all be confirmed through testing ARINC 818 systems. Extensive testing protocols minimize the possibility of costly errors and guarantee optimal performance in real-world applications by assisting in the early identification and correction of possible problems.

A. Preparing for Testing

- Establishing Testing Environment: Accurate testing requires a regulated environment to be set up. This includes making sure that the signal connections, power supply, and ambient factors like humidity and temperature are all in working order.

- Required Equipment and Tools: Comprehensive testing requires test tools like oscilloscopes, signal generators, and protocol analyzers. It might also be necessary to use specialized software tools to analyze protocol compliance and data packets.

B. Functional Testing

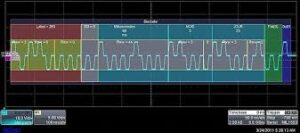

- Verifying Signal Integrity: Ensuring that data is reliably delivered and received without mistakes or corruption is ensured by testing the integrity of signals transmitted across ARINC 818 lines. This includes assessing the synchronization, noise levels, and signal quality.

- Assessing Data Transmission: Verifying the transmission of audio, video, and control data over ARINC 818 links is a component of functional testing. This entails checking that video streams are routed and shown correctly and testing the control signals’ responsiveness.

C. Performance Testing

- Bandwidth and Throughput Evaluation: It is ensured that ARINC 818 lines can support the necessary data rates without degradation or bottlenecks by testing their bandwidth and throughput. This entails determining the maximum data transfer rate and evaluating how long the system can maintain it.

- Latency Measurement: When it comes to applications where instantaneous response is crucial, latency—the interval between data transmission and reception is crucial. By testing latency, ARINC 818 systems can be made sure to provide data on time and in compliance with latency standards.

D. Protocol Compliance Testing

- Ensuring ARINC 818 Compliance: The data transmission protocol, including data formats, frame structures, and timing criteria, is defined by the ARINC 818 specifications. Compliance testing makes certain that ARINC 818 systems follow these guidelines and interoperability requirements.

- Conformance to Specific Standards: Testing may also involve adhering to industry-specific standards or client needs in addition to the ARINC 818 requirements. Compatibility testing with avionics systems, military standards, and other regulatory requirements may fall under this category.

To guarantee ARINC 818 systems’ dependability, interoperability, and compliance with industry standards, thorough testing entails a mix of functional, performance, and compliance testing.

Developers can find and fix such problems early in the process, leading to more durable and dependable systems for aerospace and defense applications, by adhering to established testing protocols and best practices.

Validation of ARINC 818 Systems

A critical first step in making that ARINC 818 systems satisfy the necessary requirements, operate dependably, and are secure for deployment in the intended applications is validation. In this phase, it is ensured that the system performs as planned, follows established procedures, and is resilient to a range of operating environments. Key components of ARINC 818 system validation procedures are as follows:

A. Validation Methodologies:

Test Plans and Procedures:

- Develop comprehensive test plans outlining the validation objectives, methodologies, test cases, and success criteria.

- Define clear procedures for executing tests, capturing data, and analyzing results.

- Ensure that the test plans cover all relevant aspects of the ARINC 818 system, including functionality, performance, and safety.

Simulation and Emulation Techniques:

- Utilize simulation and emulation tools to recreate real-world scenarios and test system behavior under different conditions.

- Simulate ARINC 818 data streams, traffic patterns, and environmental factors to evaluate system responses.

- Emulate various components of the system, such as display units and avionics computers, to assess interoperability and compatibility.

B. Performance Validation:

Benchmarking Against Specifications:

- Compare the performance of the ARINC 818 system against industry standards and specifications.

- Measure parameters such as bandwidth, throughput, latency, and jitter to ensure compliance with requirements.

- Conduct benchmark tests under typical operating conditions as well as extreme scenarios to assess system scalability and resilience.

Real-world Scenario Testing:

- Validate the ARINC 818 system in real-world environments relevant to its intended application.

- Test the system under normal operating conditions, as well as in challenging scenarios such as high vibration, temperature extremes, and electromagnetic interference.

- Evaluate system performance during critical phases of operation, such as takeoff, landing, and in-flight maneuvers.

C. Reliability and Safety Validation:

Stress Testing and Failure Analysis:

- Subject the ARINC 818 system to stress tests to identify its limits and potential failure points.

- Apply stressors such as high data loads, network congestion, and hardware malfunctions to assess system robustness.

- Perform failure analysis to understand the root causes of any observed failures and develop mitigation strategies.

Redundancy and Failover Testing:

- Validate the effectiveness of redundancy and failover mechanisms in the ARINC 818 system.

- Test failover processes for seamless transition between redundant components in case of failure.

- Verify that backup systems can maintain critical functionality and data integrity during primary system failures.

Challenges and Best Practices

A. Common Challenges in Testing and Validation

- Compatibility Issues: Compatibility issues arise because ARINC 818 systems frequently need to interface with different hardware and software components. Interoperability problems during testing may arise from varying equipment specifications or different standard implementations.

- Signal Integrity and Noise: It might be difficult to maintain signal integrity across extended wire lengths or in EMI-prone settings. Ensuring dependable data transmission requires testing for noise susceptibility and signal degradation.

- Timing and Synchronization: In an ARINC 818 system, it can be difficult to achieve exact timing and synchronization between several components. In applications where latency must be kept to a minimum, testing for timing accuracy and synchronization problems is crucial.

- Performance Optimization: Meeting particular bandwidth and throughput requirements can provide difficulties when it comes to ARINC 818 system performance optimization. Measuring performance indicators and pinpointing bottlenecks for optimization are critical components of testing technologies.

- Compliance and Standards Adherence: For interoperability and compatibility, ARINC 818 standards and specifications must be followed. But applying and interpreting complicated rules can result in confusion and discrepancies, necessitating extensive testing to validate compliance.

B. Best Practices for Successful Testing and Validation

- Comprehensive Test Planning: Provide comprehensive test plans that address functional, performance, and compliance testing, as well as all facets of ARINC 818 functioning. To successfully guide the testing process, define the acceptance criteria, expected outcomes, and test scenarios.

- Use of Test Automation: To increase efficiency and streamline the testing process, use test automation wherever it is practical. Repetitive test cases can be regularly executed by automated test scripts, saving manual labor and lowering the chance of human error.

- Realistic Test Environments: To ensure that test results are genuine, provide test environments that closely mimic actual operational conditions. To faithfully replicate real-world usage scenarios, use representative data, device setups, and environmental variables.

- Collaboration and Communication: To promote information exchange and problem-solving, and encourage cooperation between the development, testing, and validation teams. Aligning all stakeholders on testing objectives, procedures, and outcomes is ensured through effective communication.

- Iterative Testing Approach: Use an incremental approach to testing and validation, carrying out several iterations of testing to find and fix problems. To enhance test protocols and boost overall system reliability, take into account input from previous test cycles.

- Documentation and Reporting: Keep thorough records of all tests, findings, issue reports, and remedial actions during the testing and validation process. To help resolve issues that have been identified, clear and complete reporting promotes responsibility and traceability.

Conclusion

In conclusion, learning ARINC 818 requires a thorough comprehension of its nuances as well as rigorous testing and validation of its application. This tutorial has covered the essential concepts of ARINC 818, including an examination of its elements, uses, and vital functions in contemporary avionics and aerospace systems.

To create ARINC 818 systems that are sturdy and dependable, testing and validation are essential first steps. These procedures present several difficulties, from compatibility problems to compliance issues, as was previously mentioned.

Organizations may overcome these obstacles, though, if they follow best practices like thorough test preparation, test automation, and realistic test environments.

Moreover, effective testing and validation procedures depend on interdisciplinary teams’ cooperation and communication. In order to guarantee that ARINC 818 systems meet strict performance, reliability, and safety criteria, businesses can take advantage of collective experience to detect and swiftly address issues by creating synergy between development, testing, and validation teams.

As testing technologies expand, ARINC 818 standards and protocols will continue to evolve, offering new and exciting opportunities for innovation and improvement. Organizations may stay on top of the game and open up new avenues for aerospace and avionics applications by keeping up with these advances and adopting emerging trends.